Custom Performance Clutch Manufacturer in China, since 2004

Customized Performance Clutch Manufacturer

In the realm of high-performance clutch manufacturing, prominent brands may offer proprietary brand programs, but these often come with a high cost and stringent procurement policies that are not sustainable in the long term. Moreover, sourcing internationally poses its own set of challenges due to the multitude of suppliers. Some of these suppliers may, in fact, be mere “trading companies” or intermediaries, forwarding your orders to manufacturers, while others might only specialize in OEM replacement clutches.

At SPEEDE, we have dedicated over a decade to crafting high-performance clutches for compact sports vehicles. The inception of SPEEDE was driven by the belief that superior quality high-performance components and affordability should not be mutually exclusive. Our mission is to offer an alternative for small businesses when the rigid brand-name procurement policies prevent them from owning their brand of high-performance clutches.

Since 2009, we have been engineering high-performance versions of stock clutches for nearly every popular application in the market. Whether your focus is on Subaru, Mitsubishi, Mazda, Nissan, or Volkswagen, SPEEDE is equipped to provide the high-performance clutch you need. Our approach is not just about manufacturing; it’s about crafting a legacy of performance and reliability, tailored to the needs of small enterprises and enthusiasts alike.

Stage I, HD Organic

Stage II, Segmented Ceramic

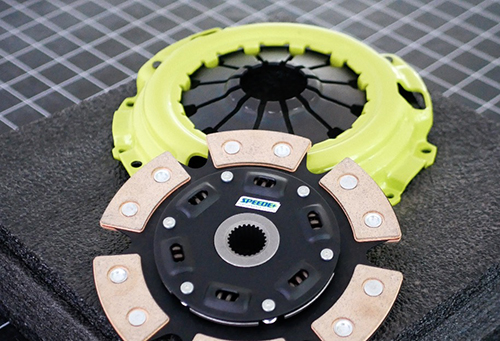

Stage III, 6-puck Ceramic

REQUEST A QUOTE FOR MORE DETAILS

REQUEST A QUOTE FOR MORE DETAILS

Rev Up Your Engine: The Guide to Choosing the Right Performance Clutch

Are you aching to rev up your vehicle’s engine and experience the thrill of a high-performance ride? Look no further than our guide to choosing the right performance clutch for your vehicle. When it comes to maximizing power and speed, selecting the perfect clutch is essential. But with so many options available, it can be overwhelming to determine which one is right for your specific needs. In this comprehensive guide, we’ll walk you through everything you need to know about performance clutches. From understanding the different types of clutches to considering factors like torque capacity and material construction, we’ve got you covered. Whether you’re a seasoned car enthusiast or a casual driver looking to enhance your vehicle’s performance, this guide will give you all the information you need to make an informed decision. Get ready to take your driving experience to the next level with the perfect performance clutch.

Understanding the importance of a performance clutch

A performance clutch is a crucial component of any high-performance vehicle. It plays a vital role in transferring power from the engine to the wheels, allowing you to control the speed and acceleration of your vehicle. Unlike a standard clutch, which is designed for regular driving conditions, a performance clutch is specifically engineered to handle the increased power and torque generated by high-performance engines. When it comes to maximizing the performance of your vehicle, a performance clutch is essential. It allows you to harness the full potential of your engine, providing quicker and smoother gear changes, improved acceleration, and enhanced overall performance. Whether you’re hitting the racetrack or simply want to enjoy a more exhilarating driving experience on the open road, a performance clutch is a must-have upgrade. But choosing the right performance clutch can be a daunting task. With so many options available, it’s important to understand the different types of clutches and the factors to consider when making your selection.

Different types of clutches for performance vehicles

When it comes to performance clutches, there are several types to choose from. Each type has its own unique characteristics and advantages, so it’s important to understand the differences to make an informed decision.

Light Performance Clutch: HD Organic

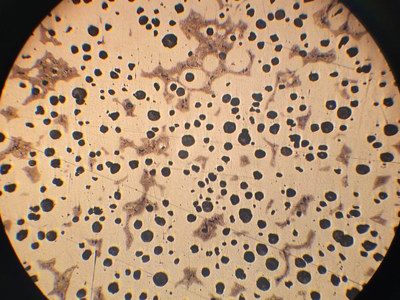

Organic clutches are the most common type of performance clutch. They are made from a blend of organic materials, sometimes adding brass, and provide a good balance between performance and daily drivability. Organic clutches offer smooth engagement, low pedal effort, and are suitable for most high-performance applications.

Medium Performance Clutch: Segmented Ceramic

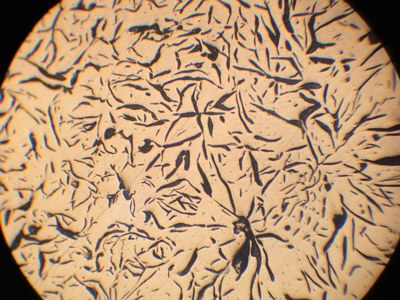

Segmented Ceramic clutches are designed for medium-performance applications that require increased torque capacity. They are made from a mixture of ceramic materials and offer improved heat resistance and durability. Segmented ceramic clutches provide a more aggressive engagement and are ideal for vehicles with high horsepower and torque outputs.

Heavy Duty Performance Clutch: 6-Puck Ceramic

6-puck Ceramic clutches are higher version of the segmented ceramic clutches. They are designed for high-performance applications that require increased torque capacity than the above two applications. They are also made from a mixture of ceramic materials and offer improved heat resistance and durability. 6-puck ceramic clutches provide a more aggressive engagement and are ideal for applications such as drifting, dragging, and circuit racing.

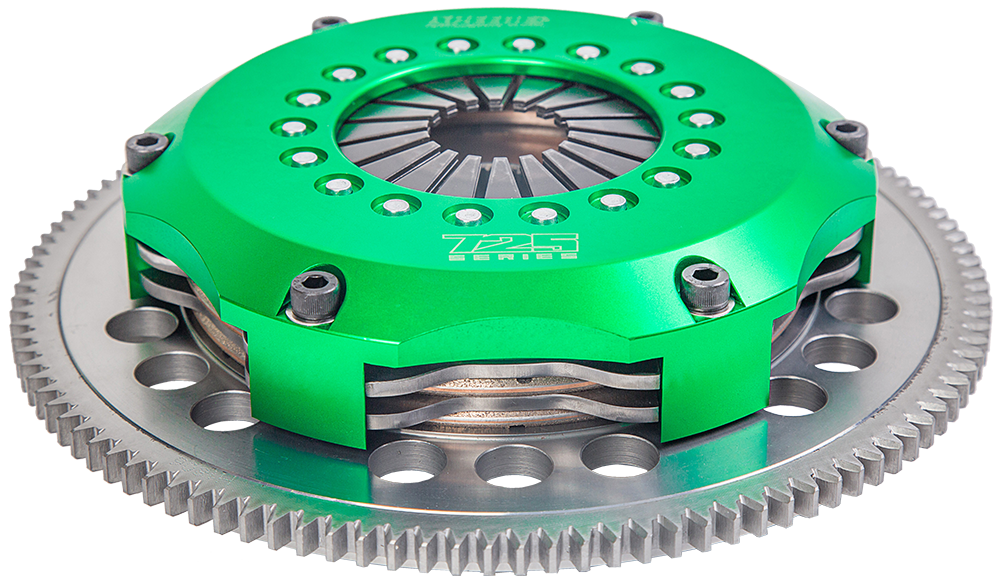

Racing Clutch: Multi-disc Ceramic

Multi-disc clutches are designed for extreme high-performance applications. They feature multiple discs and offer the highest torque capacity of any clutch type. Multi-disc clutches provide lightning-fast gear changes and are commonly used in racing and track-oriented vehicles.

Factors to consider when choosing a performance clutch

Selecting the right performance clutch for your vehicle requires careful consideration of several factors. These factors will help ensure that you choose a clutch that is compatible with your vehicle’s power output, driving style, and intended use. Let’s take a closer look at the key factors you should consider when making your decision.

Torque Capacity: The torque capacity of a clutch refers to the maximum amount of torque it can handle without slipping. It is crucial to choose a clutch that can handle the torque output of your vehicle’s engine. Failure to do so can result in clutch slippage, reduced performance, and potential damage to the clutch and other drivetrain components.

Driving Style: Your driving style plays a significant role in determining the type of clutch that is best suited for you. If you engage in aggressive driving or participate in track events, a clutch with a higher torque capacity and more aggressive engagement may be ideal. On the other hand, if you primarily use your vehicle for daily commuting, a clutch with a smoother engagement and lower pedal effort may be more suitable.

Intended Use: Consider how you plan to use your vehicle. If you’re building a high-performance street car, a clutch that offers a good balance between performance and daily drivability is recommended. However, if you’re building a dedicated track car or drag racer, a clutch with a higher torque capacity and more aggressive engagement may be necessary to handle the demands of intense racing conditions.

Now that you have a better understanding of the factors to consider when choosing a performance clutch, let’s explore the impact of clutch materials on performance.

Materials and their impact on performance clutch

The material used in a performance clutch greatly influences its overall performance and durability. Different materials offer varying levels of heat resistance, friction characteristics, and wear resistance. Understanding the properties of different clutch materials will help you make an informed decision when selecting a clutch for your vehicle.

Pressure Material: Diaphragm Spring 65Mn vs 51CrV4

The diaphragm spring of a clutch pressure plate is a key component ensuring the proper functioning of the clutch, directly affecting the engagement and disengagement of the clutch. In terms of material selection, 65Mn and 51CrV4 are two common options, each with their distinct characteristics and suitable applications.

65Mn is a type of high-carbon spring steel containing a certain proportion of manganese, providing good strength and hardness.

- Advantages: The main advantages of 65Mn include high strength, good elasticity, and excellent wear resistance. This makes it suitable for diaphragm springs that require higher strength and durability.

- Applications: For standard to medium-load automotive clutches, 65Mn is an economical and effective choice.

51CrV4 is a superior grade of spring steel containing elements of chromium and vanadium, which endow it with enhanced mechanical properties and heat resistance.

- Characteristics: 51CrV4 maintains good strength and toughness even at high temperatures, which is crucial for clutch pressure plates in high-performance or heavy-load applications.

- Usage: For high-performance vehicles, heavy-duty vehicles, or clutches operating under extreme conditions, 51CrV4 is a more suitable choice.

Material Comparison

- Strength and Wear Resistance: Although both materials have good strength and wear resistance, 51CrV4 performs better under extreme conditions.

- Heat Resistance: 51CrV4 has notably better heat resistance than 65Mn, which is particularly important in high-temperature environments.

Friction Material: Organic vs Ceramic

Clutches made from organic materials, offer a good balance between performance and daily drivability. They provide smooth engagement, low pedal effort, and are suitable for most high-performance applications. However, organic clutches have a limited lifespan and may not withstand the high heat generated by extreme racing conditions.

Ceramic clutches are designed for high-performance applications that require increased torque capacity. They are made from a mixture of ceramic materials and offer improved heat resistance and durability. Ceramic clutches provide a more aggressive engagement and are ideal for vehicles with high horsepower and torque outputs. However, they can be harsher on the drivetrain and may require a break-in period to optimize performance.

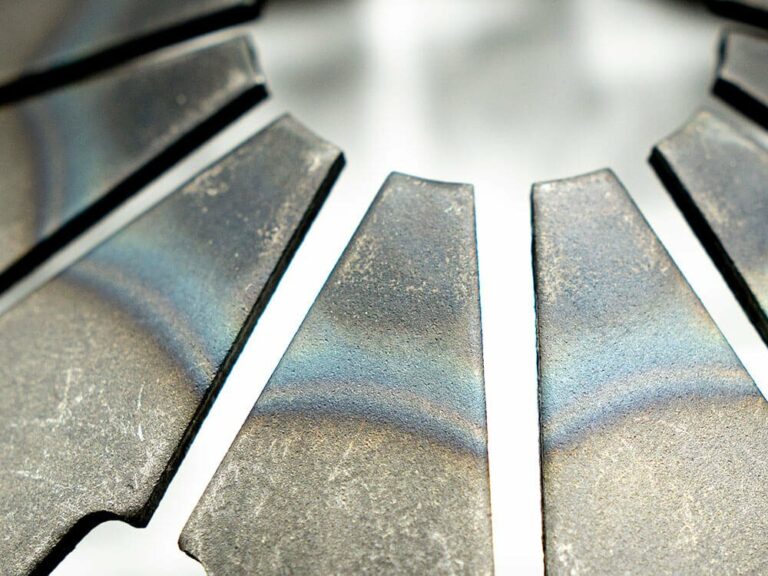

Casting Material: Ductile Iron vs Gray Iron

Ductile iron and gray iron each have their unique advantages in the application of clutch pressure plates. Clutch pressure plates used in high-performance cars and racing vehicles require materials with superior wear resistance and load-bearing capacity, especially those that can excel under impact and stress.

Ductile iron is a type of high-strength cast iron, primarily characterized by its spherical graphite content. This structure endows ductile iron with higher strength and toughness while maintaining a certain level of ductility. Ductile iron surpasses grey iron in terms of strength and durability, and due to its high strength, it can even be designed thinner, thus reducing weight. This reduction in weight is beneficial for enhancing vehicle performance and fuel efficiency.

Gray iron, containing flake graphite, displays good compressive strength and shock absorption capacity but has less ductility. It is suitable for standard vehicle clutch pressure plates, especially under normal driving conditions, providing sufficient performance and durability.

SPEEDE Clutch's Innovative Breakthrough

Effortless Control: Enhancing Clamping Force while Keeping the Pedal Light

In the realm of clutch design, creating heavy-duty, high-performance clutches capable of handling high loads and exhibiting exceptional friction coefficients is relatively straightforward. However, the real challenge lies in achieving this without increasing pedal pressure.

For 15 years, our clutches have been put to the test on streets, highways, and racetracks around the globe. Through in-depth analysis of over a thousand well-known clutches, coupled with valuable feedback from our customers, we’ve developed our unique clutch reinforcement system.

- 4-stage heat-treated diaphragm spring

- Thicker diaphragm springs

- Optimized cone angles to enhance downward pressure

- An innovative, adjustable lever system

Historically, many clutch brands on the market have increased clamping force through the first two methods, but this often led to a harder pedal feel and could cause premature wear of the thrust bearing, affecting shift quality and even damaging clutch and engine components. At SPEEDE Clutch, however, we believe that increasing clamping force doesn’t have to mean sacrificing pedal lightness. By combining the above innovative techniques, our light and medium-duty products successfully achieve enhanced clamping force without increasing pedal pressure.

Our clutches are not only suitable for racing but also enhance the everyday driving experience. SPEEDE Clutch represents the perfect fusion of performance and comfort, showcasing the power of technological innovation.